Chillers, passive cooling and oil cooling solutions

Applied Thermal Control offers over 40 years of expertise in crafting high-quality, precise recirculating chillers, water to water heat exchangers, and airblast coolers in the UK. Our products stand out for their compact design, quiet operation, and exceptional temperature stability of up to 0.1°C, ensuring optimal performance and reliability for manufacturing and laboratory processes. We pride ourselves on our collaborative approach, working closely with both end users and original equipment manufacturers to deliver tailored solutions that meet specific application needs. From product development to manufacture, installation, and servicing, ATC provides comprehensive support. Our global distributor network, supported by trusted partners, ensures consistent, high-standard service worldwide.

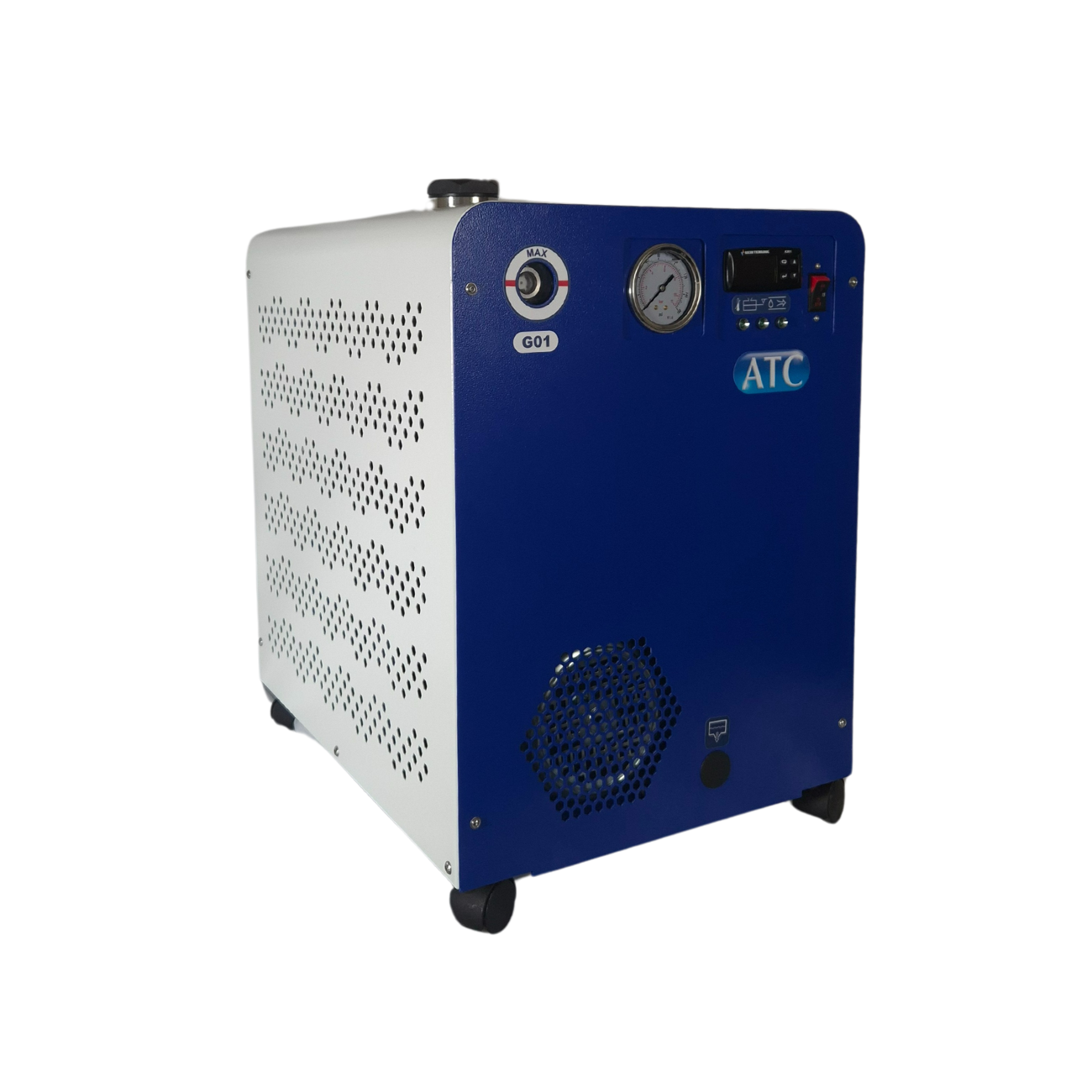

Recirculating Chillers

Applied Thermal Control specialises in providing versatile and robust recirculating chillers, catering to a diverse range of applications from laboratories to industrial processes. Compact and designed for flexibility, ATC laboratory chillers feature a small footprint, quiet operation, and precise temperature control with an accuracy of up 0.1% and cooling capacities up to 15kW. The range includes models using natural R290 refrigerant, offering high performance with lower environmental impact, and rack-mounted chillers designed for seamless integration into existing systems. Additionally, ATC supplied industrial chillers from ef Cooling, known for their efficiency and reliability in demanding environments.

Globally compatible and UL-CSA compliant, ATC ensures comprehensive support through a network of skilled service agents and offers service contracts for enhanced operational service.

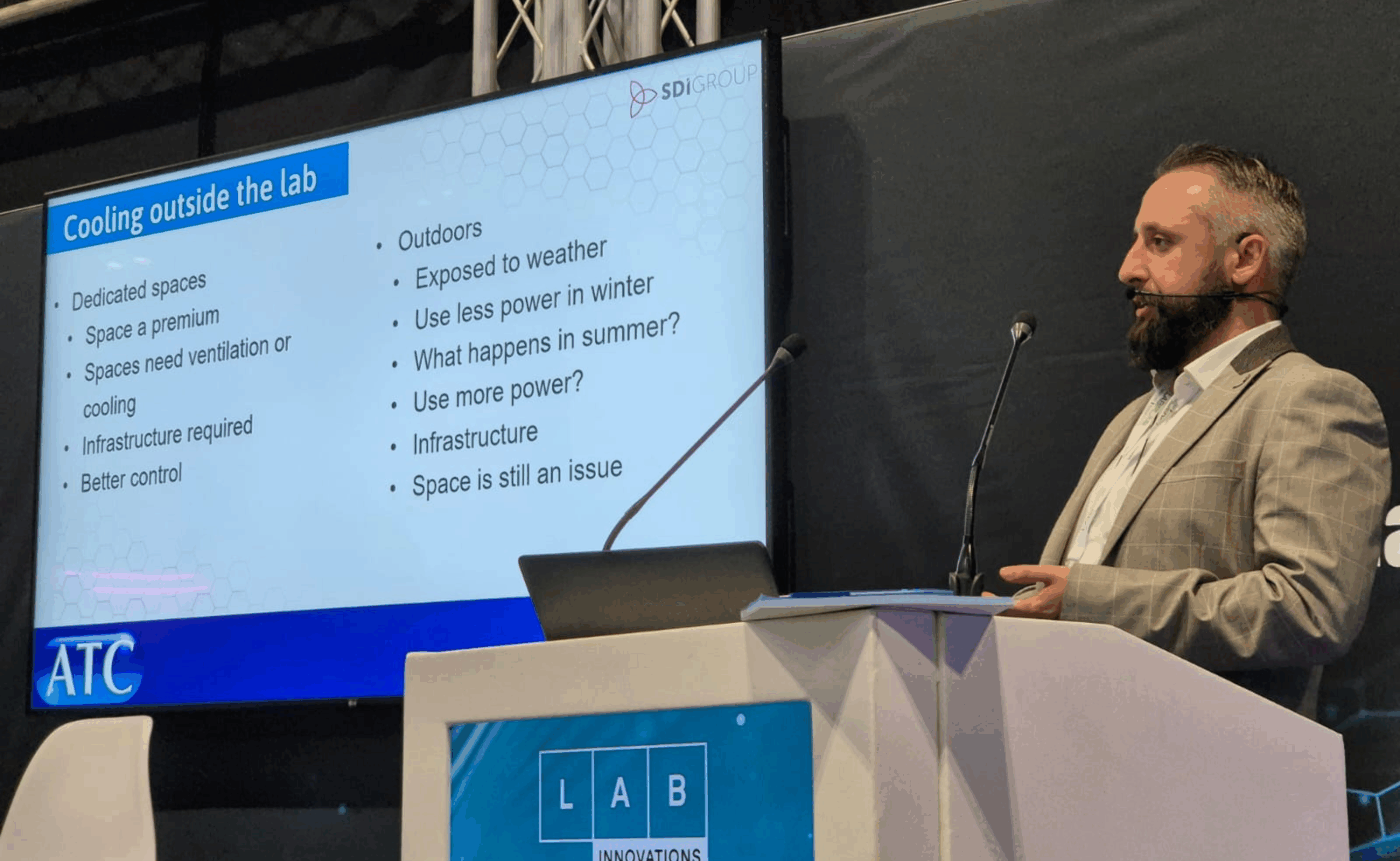

Passive Cooling

Applied Thermal Control offers a comprehensive range of passive cooling equipment, including airblast coolers and water-to-water heat exchangers. The airblast coolers utilise ambient air for cooling processes, efficiently removing heat without refrigeration, making them ideal for various industrial applications. Meanwhile, the water-to-water heat exchangers are designed for seamless integration with primary cooling circuits, providing a stable coolant supply and protecting sensitive equipment. Both solutions are tailored to meet specific customer needs, ensuring optimal performance in laboratory and industrial settings.

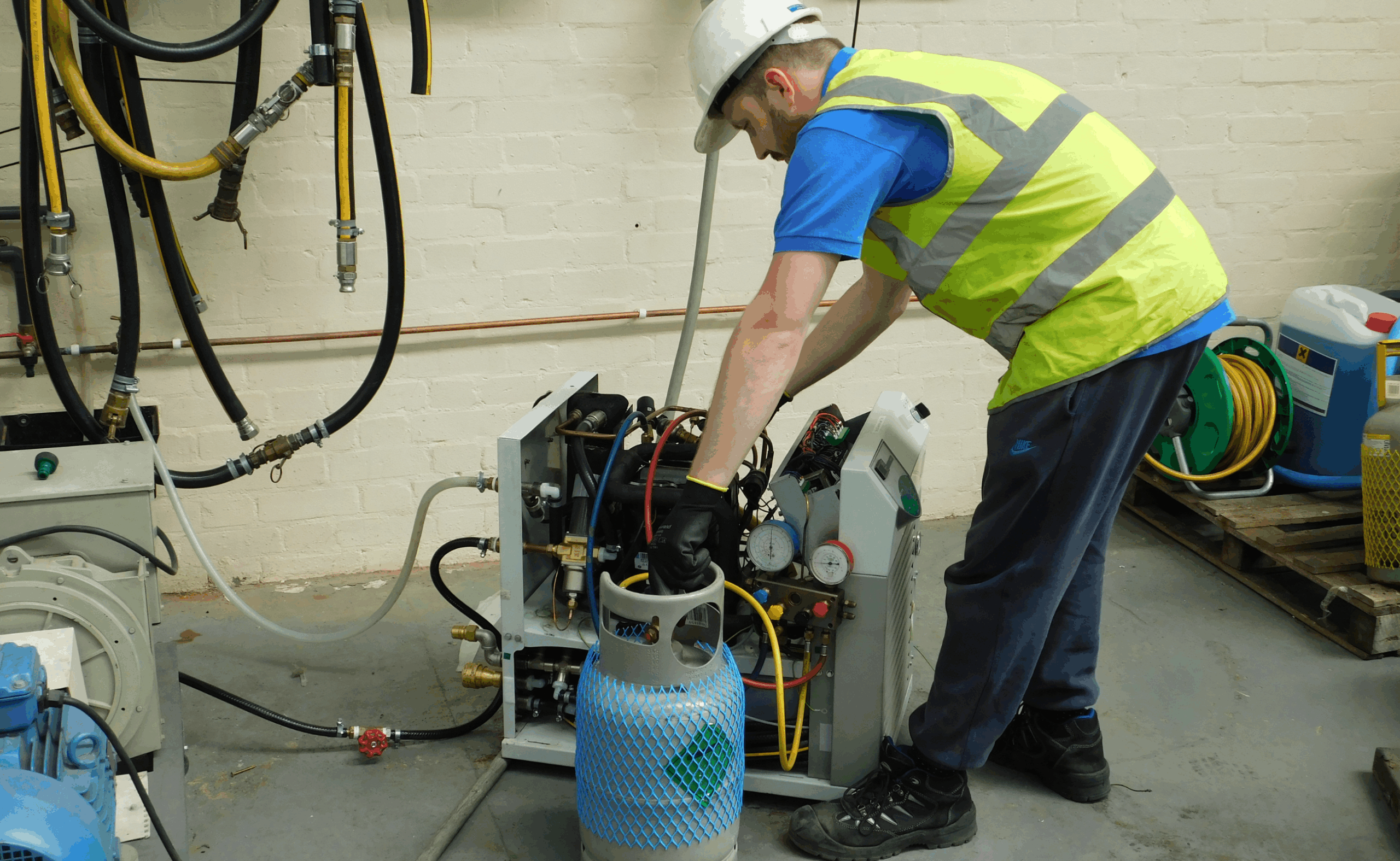

Oil Cooling

Oil provides several advantages over air and water cooling, making it especially effective for high-temperature operations, electrically sensitive applications, and corrosive environments. It’s particularly useful for applications requiring electrical insulation or those operating above water’s boiling point. Since oil is non-conductive, it can be safely used in high-voltage areas or with sensitive electrical components, adding an extra layer of protection against electrical hazards. Additionally, oil has a higher boiling point than water, enabling it to maintain stable thermal properties at temperatures where water would vaporise. This ensures consistent cooling performance under extreme conditions, making oil an excellent choice for cooling systems that must operate at high temperatures without the risk of boiling and the consequent pressure build-up and system failure.