MGR

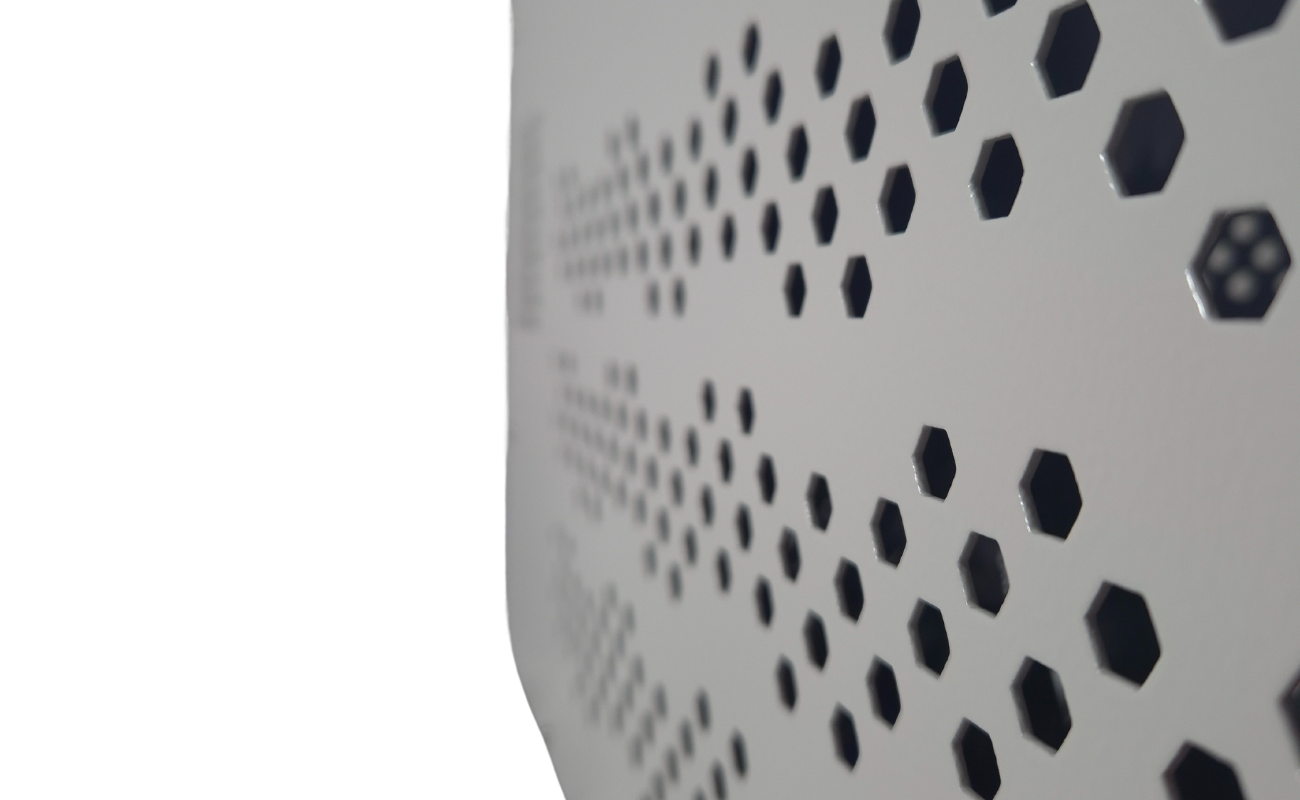

The MGR recirculating chiller from Applied Thermal Control is a space-saving, environmentally friendly cooling solution designed for laboratory and industrial applications. The MGR replaces the KTR model, offering enhanced efficiency and sustainability while maintaining reliable temperature management with a cooling capacity of 0.5kW*.

Its eco-conscious design incorporates R290, a natural refrigerant, ensuring full compliance with environmental regulations and a reduced environmental impact without compromising performance.

*0.5kW cooling capacity at a +20°C set point in a 20°C ambient environment.

Enclosure Size

Height 428mm

Width 220mm

Depth 516mm

Width 220mm

Depth 516mm

Power Supply Options

(115Vac, 1~, 60Hz) 1-spec

220-240Vac, 1~/2~, 50/60Hz 5-spec

220-240Vac, 1~/2~, 50/60Hz 5-spec

Cooling Capacity

500W Cooling Capacity (Ambient Dependent)

Temperature Range

+4°C – +35°C (standard)

-10°C – +35°C (extended)

-10°C – +35°C (extended)

Document downloads

MGR – 500W Recirculating Chiller

0.5kW

Administrative Data

ATC Model Name

MGR

ATC K-Series Equivalent

KTR

Physical Attributes

Physical dimensions (mm)

Height 428mmrnWidth 220mmrnDepth 516mm

Construction

Sheet steel gauge 1.5mm.rnPowder coated

Mounting Type

Benchtop

Acceptable Environment

Indoors (standard)

Dry Weight (kg)

30kg

Wet Weight (kg)

31kg

Noise Level (dB(A)) at 1 meter

Product IP Rating

IP20

Toolless Access

No

Enclosure Drawing Number

MA890

Airfreight

Send charged

Sea Freight

Send charged

Temperature Control Attributes

Cooling/Refrigeration Technology

Vapour Compression

Compressor Type

Reciprocating

Evaporator Technology

Brazed Plate Heat Exchanger (BPHE)

Duty at +20°C ambient, Setpoint +20°C (kW)

0.5kW

Refrigerant u0026 Charge

R290, 90g

Ambient Temperature Range (standard)

+4°C to +25°C

Control Method

None – HGBP only

Temperature Stability (with constant load)

±0.1˚C

Temperature Resolution

±0.1˚C

Maximum Total Heat Rejection

600W

Cooling Fan Airflow

73cfm

Water Circuit Attributes

Designed Nominal Process Fluid Flowrate

3lpm

Design Nominal Pressure

2 Bar

Process Temperature Range (Standard)

+4 to +35°C

Process Temperature Range (Extended Low Temp)

-10°C

Process Temperature Range (Extended High Temp)

60°C trip

Maximum Return Line Temperature (Standard)

60°C trip

Maximum Return Line Temperature (Extended)

60°C trip

Pump Options

3lpm 24V pump only

Visible Level Indicator

Yes

Integrated Drain

No

System Volume

0.85l

Tank Type

Flow-through

Flow and Pressure Control

Not Available

Connection Size (fittings to convert size as needed available)

12mm push-fit

Construction Materials

Steel enclosure

Fluid Compatibility

Hexid Fluid, Sterile Water

Electrical Attributes

24VDC – L-Spec

–

(90-264Vac, 1~/2~, 50-60Hz) U-spec

–

(230Vac, 1~, 50Hz) 0-spec

–

(115Vac, 1~, 60Hz) 1-spec

Available, 3.5A

(208-220Vac, 1~/2~, 60Hz) 2-spec

–

(400Vac, 3~, 50Hz) 3-spec

–

(460Vac, 3~, 60Hz) 4-spec

–

220-240Vac, 1~/2~, 50/60Hz 5-spec

Available, 2.7A

(Switchable 208Vac, 1~/2~, 60Hz | 220Vac, 1~/2~, 60Hz | 230Vac, 1~, 50Hz) 6-spec

–

(Switchable 115Vac, 1~, 60Hz | 230Vac, 1~, 50/60Hz) 7-spec

Available, see SA63

(208Vac, 3~, 60Hz) 8-spec

–

(208-230Vac, 1~/2~, 50/60Hz) 9-spec

–

Safety Interlocks, Protections, Standards, and Indicators

1st Party Approvals

CE,UKCA

3rd Party Approvals

–

Empty Fluid Reservoir Alarm

Process stop interlock

Low Fluid Flow Alarm

–

Temperature Out of Range Alarm

–

Compressor HP Switch

Standard

Interlock Restored, Restart Mode

Automatic

Overcurrent Fault-Cleared Restart Mode

Manual

Overcurrent Protection

Fused

Motor Thermal Overload

–

Warranty Options

2 year parts, 1 year labourrnEnhanced warranty options